We often take electricity for granted, but within wires and electrical gear lurks the potential for hazards if mishandled – including the phenomenon known as an arc flash. Have you received proper training on electrical explosion risks? Or confirm the arc flash rating on equipment before beginning work?

If not, it’s time to learn more. When an arc flash erupts, the results can be catastrophic, causing severe injuries and collateral damage. However, armed with the right protective knowledge, gear, and prevention systems, you can help achieve arc flash safety at your workplace.

What Defines An Electrical Arc Flash?

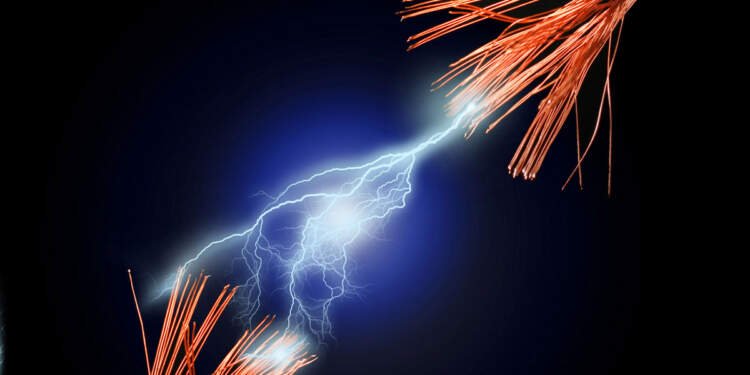

An arc flash refers to the explosive release of energy triggered when electricity arcs between conductors or from a conductor to the ground. The arc superheats the surrounding air to temperatures exceeding 35,000°F!

Within milliseconds, this arc flash unleashes a destructive blast wave along with shrapnel, heat, UV radiation, and gasses. This can lead to major injury or even death without proper safety measures. With so much power behind it, an arc flash poses serious risks you can’t overlook.

What Triggers An Arc Flash?

Various factors can trigger these dangerous electrical explosions:

- Accidental contact with live components

- Dust or impurities lowering insulation resistance

- Corrosion or damage to enclosures

- Dropped tools/debris causing a short circuit

- Errors modifying circuits while energized

Essentially, an arc flash results from unintended current flows between live parts. These dangerous faults are usually caused by human error or equipment failures around electrical systems.

Protecting Yourself from Arc Flash Hazards

Thankfully, you can take vital steps to prevent electrical arc flash accidents and protect yourself should one occur. Select proper arc-rated PPE and plan safe work practices, as these make a huge difference in terms of safety.

Arc flash analysis is also necessary to calculate your equipment’s prospective arc flash energy. IEEE 1584 provides an empirical model for estimating available thermal energy during an arc flash event. You can also have an established firm conduct the arc flash analysis and help develop your safety program.

In addition, consider the following safety measures as well:

- De-energize equipment before working whenever possible

- Ensure proper grounding, insulation, and maintenance

- Follow lockout/tagout procedures for de-energized equipment

- Cover live parts; prevent accidental contact

You must also be trained to understand arc flash risks and emergency response. Having the right gear and knowledge saves lives around electrical hazards.

Implementing Electrical Arc Flash Prevention Systems

Beyond safety gear and training, advanced arc flash prevention technologies provide an extra layer of system protection. These may include arc-resistant switchgear to contain/vent explosions, arc flash detection relays to cut power quickly, and current-limiting fuses to limit energy released.

Installing these smart technologies alongside proper procedures significantly improves arc flash safety. They aim to reduce exposure time, limit the arc blast, and prevent it from spreading. State-of-the-art protection substantially reduces accident severity and collateral impacts.

Staying Vigilant Around Electrical Hazards

Electrical arc flashes present an ever-present danger around electrical infrastructure, but with vigilance and precaution, they can be avoided. Always exercise caution when operating around live parts. Moreover, advanced safety gear, arc flash training, and arc flash analysis enable you to work confidently while steering clear of disaster.